Investigation of phases and microstructures of novel ternary ceramic coatings with the help of Synchrotron CT and Diffraction

Gulhfi AG is an international innovation leader in surface engineering and provides contract design, prototyping service and specific powder material and coating systems for such thermal spray equipment. Gulhfi is specialized in thermal spray coating technology in particular for medical, energy, aerospace, automotive and general industry like the printing industry. The core technology of Gulhfi is to provide engineering services to customers. Such services imply coating development, development of new material in terms of powder and coating properties, product prototype realization, robot programming of thermal spray equipment and implementation of production line at customer site.

To further improve the properties of binary ceramic coatings, a new generation of ceramic coatings based on the combination of three single oxides are of interest to Gulhfi. The multi-metal oxides coatings can give added properties to the binary ceramic coatings, creating a new generation of highly effective coatings to improve wear, cavitation and fretting and ideally thermal shock resistance especially when high temperature is required.

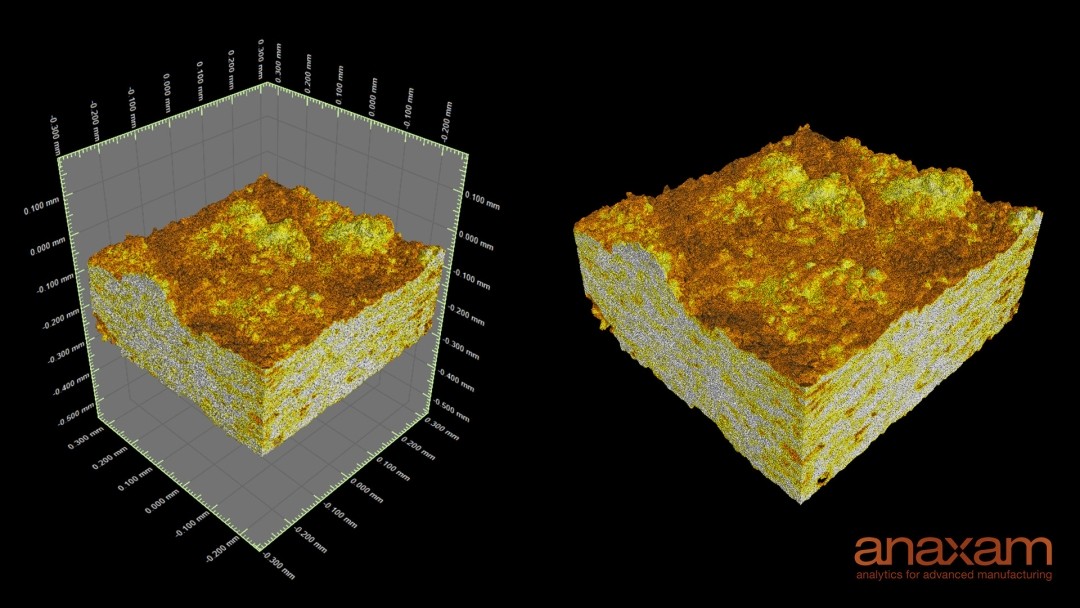

The applied material analytics of ANAXAM using Synchrotron Diffraction helps to understand the phases present in the coatings after the spraying process. Synchrotron CT is used to characterize 3-D microstructures of the coatings, such as pores, cracks and any delamination that are present. By combining the above investigations together also with electron microscopy, we were able to wrap them up into a basic “know-how-why” knowledge that can be transferred to Gulhfi for the next step towards the development and applications of multi-metal oxide coatings.

For this customer project, ANAXAM used the MS and TOMCAT beamlines at the Paul Scherrer Institute.

The analytical competences of ANAXAM offer a unique possibility compared to lab-based X-ray investigations, in order to develop a robust ceramic surface for the new generation of ternary ceramic oxide coatings.”

Dr. Armando Salito, Director,Gulhfi AG