Investigation of fiber distribution in fiber-reinforced plastic components using high-resolution Synchrotron CT

Huba Control AG develops, manufactures and sells components for recording the physical variables of pressure and flow. These include pressure switches, sensors and pressure transmitters (sensors with integrated amplifier electronics). The clear focus on pressure and flow measurement technology allows the development of innovative products. A diverse range of products makes it possible to meet the most varied requirements for improving processes in systems, machines and plants. In order to meet the constantly increasing market requirements, Huba Control AG is constantly striving to expand its product portfolio through new and further developments of sensors. In the field of flow measurement technology in particular, there is strong market growth and a clear trend towards more robust and durable sensors.

In order for a company with a production site in Switzerland to survive on the international market, it must score points with quality and innovation. ANAXAM was able to make an important contribution here.

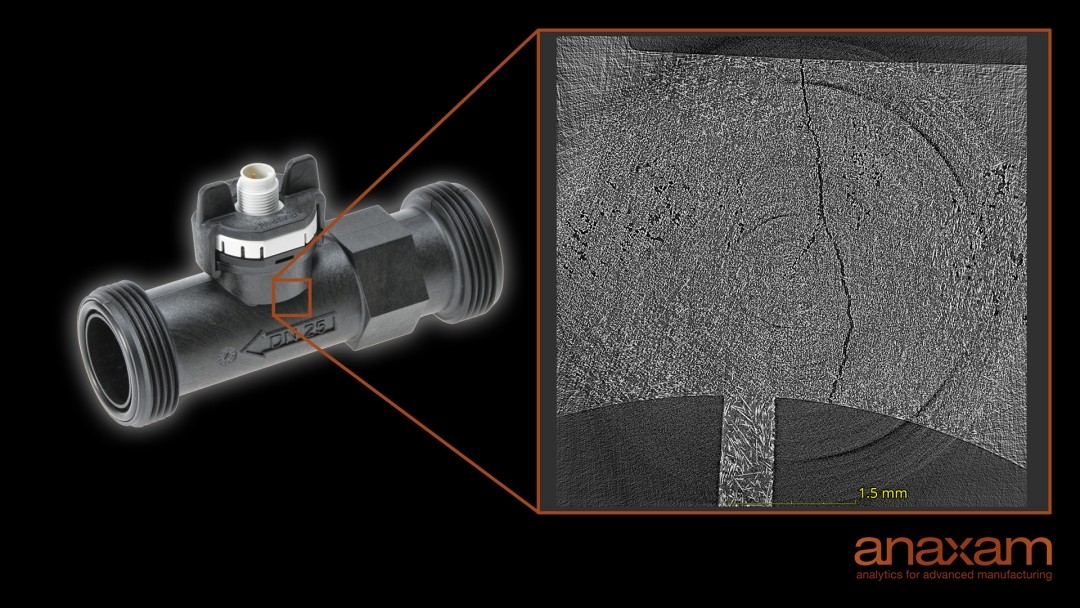

ANAXAM's applied material analytics using high-resolution Synchrotron CT was successfully used to characterize the fibre orientation and fibre density in the plastic component.

The analytics results helped Huba Control AG to optimize the alignment and course of the glass fibres in the fibre-reinforced plastic injection-moulded part of the measuring tube. ANAXAM's analytics thus made a decisive contribution to increasing the robustness of the sensors. Future products will be able to withstand pressure surges of up to 100 bar, even at high medium temperatures.

For this customer project, ANAXAM used the TOMCAT beamline at the Paul Scherrer Institute.

Thanks to ANAXAM's CT expertise, we were able to accelerate our development project many times over and raise the quality to the level we had set as our goal.”

Samuel Winkler, Project Manager Product Development,Huba Control AG