Design and construction of a cryochamber for the investigation of Arctic sea ice and spray ice samples by means of high-resolution Synchrotron CT

Within the framework of a joint development project between the Norwegian University of Technology and Natural Sciences (NTNU), the industrial partner Equinor and ANAXAM, a customised test rig in the form of a cryochamber was realised, which allows sea ice and spray ice samples to be tomographed in different temperature ranges.

The focus of the investigations was on two types of ice:

- Spray ice

This ice forms on the windward side of ships and platforms (oil & gas, wind farms, fish farms) in Arctic and sub-Arctic waters during strong swells. It poses a threat to shipping and offshore activities under extreme conditions, as a layer of ice of many centimeters can form on one side in a few hours. The microstructure of this ice, which contains a lot of saline solution, is crucial for its growth and properties, especially adhesion to surfaces. The aim of the study was to gain basic information about the microstructure of salty spray ice in order to formulate a new model for marine spray ice growth. Spray ice was produced in the NTNU ice tank and from field measurements in the Arctic (Spitsbergen) and subarctic (Norwegian fjords).

- Arctic sea ice

The sea ice samples to be examined come from the MOSAiC expedition, the largest one-year international expedition to the central Arctic to date. The aim of the investigation was to obtain a first detailed 3D image of the pore space (air, salt solution). The details of this pore space (number and size distribution, connection between pores) determine the physical properties of the sea ice, such as the reflection of solar radiation, the strength and elasticity of the ice, as well as the pore space accessible to microorganisms. They thus strongly influence the role of sea ice in the global climate system.

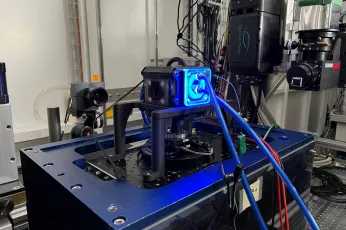

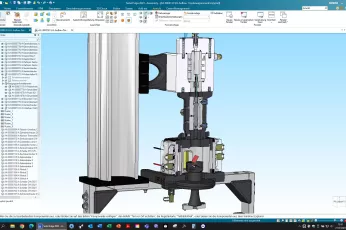

The cryochamber customised by AMAXAM allows ice samples to be measured three-dimensionally using high-resolution Synchrotron CT. For this purpose, the chamber is able to run freely programmable temperature curves down to -25°C. The temperature control accuracy is ± 0.1°C. The chamber is cooled by two Peltier elements and a liquid cooler. In the center of the chamber is the rotation axis with the holder for the samples. A total of 50 samples were measured in this way.

For this customer project, ANAXAM used the TOMCAT beamline at the Paul Scherrer Institute.

The synchrotron experiments with high-spatial resolution and good temperature control allow us to develop a physically consistent model of spray ice growth that takes into account crystal sizes and orientation as well as pores. The observations show many similarities in the microstructure of salty spray ice and sea ice. This result leads to new ways of modelling the physical properties of both types of ice.”

Dr. Sönke Maus, Scientist,Norwegian University of Technology and Natural Sciences (NTNU)