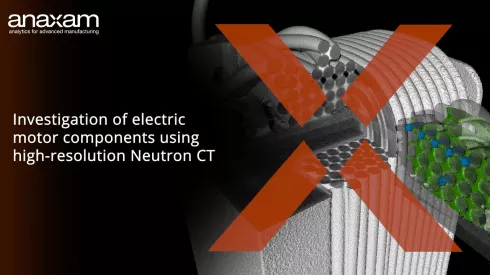

Investigation of electric motor components using high-resolution Neutron CT

As a leading global automotive and industrial supplier, the Schaeffler Group has been driving forward pioneering inventions and developments in the fields of motion and mobility for over 70 years. With innovative technologies, products, and services in the fields of CO2-efficient drives, electromobility, Industry 4.0, digitalization, and renewable energies, the company is a reliable partner for making motion and mobility more efficient, intelligent, and sustainable. The technology company produces precision components and systems for powertrains and chassis as well as rolling and plain bearing solutions for a wide range of industrial applications.

With the increasing demand for quiet electric motors with high power output, integration density, reliability and resistance in harsh environments, the quality requirements for a reliable and high-quality resin potting process are constantly rising. Different resin potting processes lead to differences in resin distribution.

Here, it is important to be able to evaluate the distribution accurately and in every layer. The resin filling must fill all cavities in order to achieve maximum durability of the electric motors. The resin distribution is decisive for high thermal conductivity and durability.

ANAXAM's material analysis by high-resolution Neutron CT was successfully applied to characterize the resin potting in electric motor windings in a non-destructive and three-dimensional manner. The analysis results helped Schaeffler to better evaluate the resin potting manufacturing process and to further optimize the process. In this way, ANAXAM's analysis made a decisive contribution to ensuring the highest potting quality.

For this customer project, ANAXAM used the NEUTRA beamline at the Paul Scherrer Institute.

ANAXAM's expertise enables us to gain new insights in the field of imaging techniques. With neutron CT, we are expanding our analysis methods to include high-precision 3D tomography.”