Providing precise calibration data with the help of Synchrotron Diffraction and a tailor-made sample delivery system

SpectraFlow Analytics (Spreitenbach) sells online measurement solutions using the Near Infra Red (NIR) technology that are mounted over conveyor belts and of raw materials processed in airslides. NIR provides phase information which enables structure determination. This online measurement solutions are used in all mineral industries, with multiple installations in the cement, iron ore, gold, platinum copper and bauxite industry. Due to the mineralogically and chemically different conditions of the raw materials, the NIR analyzer must be individually calibrated for each project based on customer-specific reference samples.

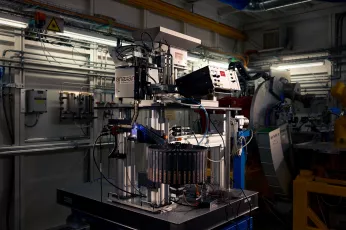

Within a project partnership ANAXAM together with SpectraFLow are building a tailor-made sample delivery system for Synchrotron Diffraction experiments. This novel infrastructure allows to upscale the amount of sample probed as well as the number of samples probed during the diffraction measurements.

Both, NIR and Synchrotron Diffraction provides the same information, namely the crystallographic phases. Here, SpectraFlow directly profit from the high-resolution phase analysis, obtained by Synchrotron Diffraction, for a very precise calibration input for their NIR online analyzing systems that finally helps SpectraFlow to improve further their product.

For this customer project, ANAXAM used the MS beamline at the Paul Scherrer Institute.

ANAXAM offers small and midsize companies as we are access to know-how and analytics a top level. Thanks to the partnership with ANAXAM we were already able to essentially improve our technology. We see a high potential that existing processes for industry can be further optimized and new processes can be developed.“