Investigation of steering systems and components by using high-resolution Neutron CT and Diffraction

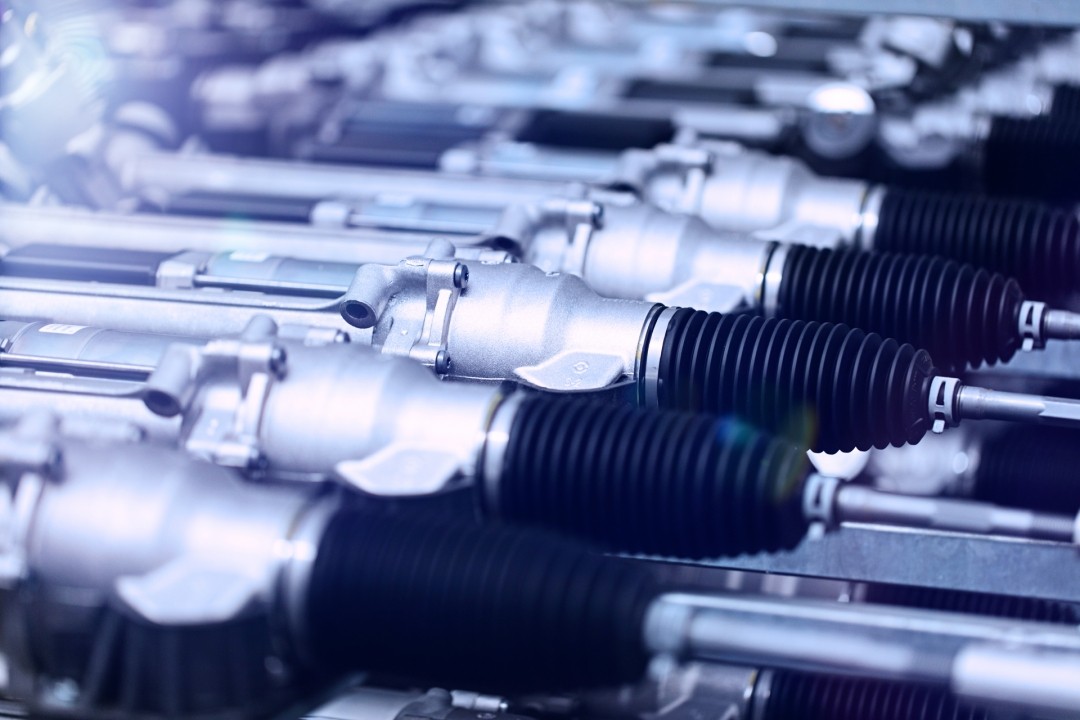

Steering systems in modern vehicles consist of many components that must interlock precisely - and for a long time. Only in this way the driver can steer precisely, reliably and safely.

Thyssenkrupp Presta AG is a company of the thyssenkrupp Group and the lead company for the thyssenkrupp Steering business area. The company is an automotive supplier headquartered in Eschen in Liechtenstein. It is one of the world's most successful manufacturers of steering systems and is a technology leader in the field of solid forging.

Applied material analysis by ANAXAM using neutron radiation helps thyssenkrupp Presta AG to optimize its products during development and to obtain important process parameters for production. Investigations with neutrons are particularly interesting because they have good complementarity with X-ray methods and enable the non-destructive investigation of complex systems such as steering systems as a whole.

Steering systems are typically designed to last several times the life of a vehicle. During this entire time, the system must function without maintenance. Lubrication is therefore carried out once during production. By using Neutron CT, it is possible to obtain detailed knowledge about grease distribution in the gears of a steering system. Together with rigorous physical tests, this information can be used to optimize the design. This ensures the highest precision and reliability over the entire service life of a steering system.

One of the ways thyssenkrupp Presta AG can ensure this reliability is by incorporating its own solid forged components into its own or customers steering systems for safety-critical applications. For such components, analysis by using Neutron Diffraction is very informative. The method allows a comprehensive and quantitative characterization of the residual stress state in the components. These findings enable an improvement in the computational design, which can reduce the experimental testing effort and thus significantly shorten the development cycle.

For this customer project, ANAXAM used the NEUTRA and POLDI beamlines at the Paul Scherrer Institute.

Neutron experiments provide important insights for the design of steering systems. Their sensitivity to lighter elements and non-destructive nature makes them a valuable complement to established industrial analytical methods.”